| 138-6173-5534 |

Wuxi Qunsheng Environmental Protection Machinery Technology co., LTD

Tel:13861735534 Mr. He

Add:Inside guorong enterprise, 9 qunsheng road, Yang industrial park, luoshe town, wuxi city, jiangsu province

Web: www.wxqshbkj.com

Website : en.wxqshbkj.com

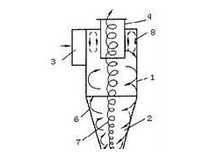

The composition of the cyclone dust collector and its internal airflow cyclone dust collector is a kind of dust removal device, its dust removal mechanism is to make the dusty airflow rotating movement, with the help of centrifugal force to separate the dust particles from the airflow and capture on the wall of the device, and then with the help of gravity to make the dust particles fall into the dust hopper.

Product overview

The cyclone began to be used in 1885 and has been developed into many types. According to the flow entry mode, it can be divided into tangential entry type and axial entry type.

1. The control range of pressure loss of cyclone dust collector is generally 500 ~ 2000Pa in terms of technology and economy.

2. Under the same pressure loss, the latter can process about three times as much gas as the former, and the airflow distribution is even.

3. Cyclone dust collector is simple in structure, easy to manufacture, install and maintain management, equipment investment and operation costs are low, has been widely used to separate solid and liquid particles from the airflow, or solid particles from the liquid. However, the ordinary cyclone dust collector is composed of cylinder, cone, inlet and exhaust pipe.

4. Under ordinary operating conditions, the centrifugal force acting on particles is 5 ~ 2500 times of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Most of them are used to remove particles of more than 3 mm. The parallel multi-tube cyclone dust collector device also has a dust removal efficiency of 90 ~ 99% for particles of 3 mm.

5. The cyclone dust collector is made of special metal or ceramic materials that are resistant to high temperature, abrasion and corrosion. It can be operated at temperatures up to 1000℃ and pressures up to 500×105Pa.